Hermetic Feedthrough Manufacturing Process Explained

3 min read

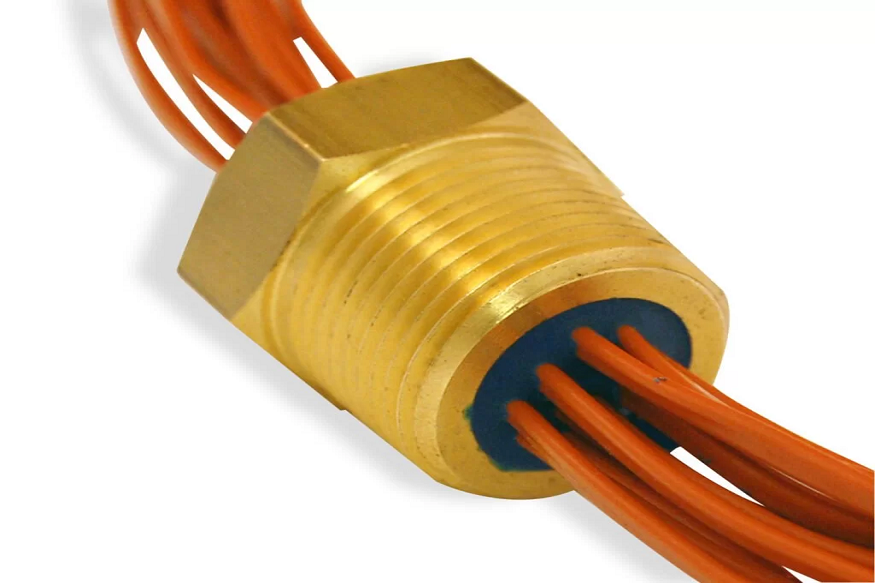

Hermetic feedthroughs are essential components used in aerospace, medical devices, industrial equipment, and scientific instruments. They allow electrical, optical, or fluid connections to pass through sealed barriers without compromising environmental integrity. The manufacturing process of hermetic feedthrough is precise and specialized, combining advanced materials, design, and assembly techniques to ensure reliability, durability, and airtight performance. Understanding this process helps engineers, designers, and buyers appreciate the quality and performance requirements of these critical components.

Step 1: Material Selection

The manufacturing process begins with selecting the right materials, which directly impacts the performance and reliability of the feedthrough. Common materials include:

- Metals: Stainless steel, Kovar, titanium for housing and pins due to strength, corrosion resistance, and thermal expansion compatibility.

- Ceramics: Alumina (Al₂O₃) for high-temperature stability, mechanical strength, and electrical insulation.

- Glass: Borosilicate or specialty glasses for vacuum sealing and dielectric insulation.

Material selection depends on the application’s requirements, including temperature, pressure, electrical load, and environmental exposure.

Step 2: Design and Engineering

Hermetic feedthroughs are designed according to application-specific requirements, such as:

- Number of connections (single-pin, multi-pin, coaxial)

- Voltage and current ratings

- Environmental conditions (vacuum, high pressure, temperature extremes)

- Mechanical stress and vibration tolerance

Computer-aided design (CAD) and finite element analysis (FEA) are often used to simulate thermal, mechanical, and electrical performance before production.

Step 3: Fabrication of Insulators

For glass-to-metal or ceramic-to-metal feedthroughs, the insulator is fabricated next. This involves shaping the ceramic or glass into the desired geometry and preparing it for integration with metal components.

- Ceramic insulators: Produced by pressing, sintering, and machining to achieve precise dimensions.

- Glass insulators: Formed through molding and annealing processes to reduce internal stress and prevent cracking.

High precision is required to ensure proper fit and sealing during assembly.

Step 4: Metal Component Preparation

Metal pins and housings are prepared to interface with the insulator. Key steps include:

- Machining metal pins to exact specifications

- Cleaning and surface preparation for bonding or brazing

- Selecting compatible alloys to match thermal expansion properties of insulators

Proper metal preparation ensures strong bonds, prevents leaks, and maintains electrical conductivity.

Step 5: Sealing and Assembly

Sealing is the most critical step in the manufacturing process. The type of seal depends on the feedthrough design:

- Glass-to-metal sealing: Metal pins are embedded in molten glass and fused to the housing.

- Ceramic-to-metal sealing: Ceramic insulators are brazed or metallized and bonded to metal components.

- Welding: Laser or electron-beam welding may be used for metal-only assemblies.

During this step, the feedthrough is inspected to ensure airtightness, electrical insulation, and mechanical strength.

Step 6: Inspection and Quality Control

After assembly, feedthroughs undergo rigorous testing to verify performance and reliability:

- Leak testing: Ensures vacuum or airtight integrity using helium mass spectrometry or pressure decay methods.

- Electrical testing: Verifies insulation, continuity, and dielectric strength.

- Mechanical testing: Evaluates resistance to vibration, shock, and thermal cycling.

- Visual inspection: Checks for defects, cracks, or imperfections in the seal.

Quality control is crucial, especially for high-reliability applications like aerospace or medical devices.

Step 7: Finishing and Surface Treatment

Finally, the feedthrough may receive surface treatments or coatings to enhance performance:

- Anti-corrosion coatings for metal housings

- Passivation to improve chemical resistance

- Polishing or plating to ensure smooth, defect-free surfaces

These finishing steps improve durability, extend service life, and enhance compatibility with specific environments.

Step 8: Packaging and Shipping

Hermetic feedthroughs are sensitive components, so they are carefully packaged to prevent damage during shipping. Protective materials, anti-static packaging, and sealed containers are used to maintain integrity until installation.

Conclusion

The manufacturing process of hermetic feedthroughs is a combination of precision engineering, advanced materials, and rigorous quality control. From material selection and design to sealing, testing, and finishing, each step is critical to ensure reliable, durable, and airtight performance. Understanding this process helps engineers and buyers appreciate the complexity and quality required for hermetic feedthroughs used in aerospace, medical, industrial, and scientific applications.

By selecting well-manufactured feedthroughs and understanding their production process, industries can ensure high-performance, long-lasting components that maintain environmental integrity under extreme conditions.