The Future Of Manufacturing: Integrating Smart Technologies

2 min read

Building a smart factory centers on leveraging advanced technology to transform production processes, boost efficiency, cut costs, and elevate overall productivity. Today, we’ll look at how a smart factory functions, employing interconnected systems, data-driven analysis, automation, and artificial intelligence (AI) to establish a responsive and adaptable production setting.

Let’s start with the Industrial Internet of Things (IIoT). IIoT connects devices via the internet, allowing for real-time data sharing and monitoring. These systems keep tabs on various factors—from machine performance to environmental conditions—offering valuable insights that aid in decision-making. With IIoT, maintenance issues can often be anticipated, reducing the risk of equipment breakdowns.

Automation and robotics are fundamental in smart factories, taking on repetitive or dangerous tasks to create a safer and more efficient workspace. Robots enable precise handling and can manage complex tasks, leading to higher-quality production and helping manufacturers quickly adjust to changes in market demands.

Machine learning (ML) adds another layer by analyzing vast data sets to optimize processes. By identifying patterns and trends, ML helps manufacturers better forecast demand and refine production schedules. Over time, this technology drives continuous improvement, resulting in smoother, more efficient operations.

Cloud computing also plays a pivotal role, offering scalable options for data storage and processing that can be accessed from anywhere. This flexibility supports real-time decision-making and lowers costs by minimizing the need for extensive on-site IT systems.

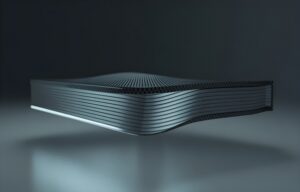

Reliable connectivity is essential to smart factories, and coaxial cable assembly from Casco Manufacturing contributes to the stability and efficiency of system communications. Using tailored cable assemblies like these minimizes downtime and ensures that the factory’s connected systems remain efficient, boosting overall productivity.

Data analytics is another powerful tool driving the success of smart factories. By examining large data sets, manufacturers can identify ways to refine workflows, eliminate inefficiencies, and anticipate future trends. This level of insight leads to smarter decisions and higher productivity.

Finally, cybersecurity has become a critical focus in smart manufacturing. With more devices and systems connected, the risk of security breaches rises. Strong protective measures, such as encryption and active monitoring, are necessary to maintain the integrity of operations and protect vital factory systems.