10 Factors to Consider When Purchasing Metal Cutting Equipment in Saudi Arabia

5 min read

Buying metal-cutting equipment is a crucial investment in any manufacturing, construction, or engineering industry. The demand for efficient and high-performance metal cutting tools has reached the sky ever since there has been an advancement in the industrial market and infrastructural development in Saudi Arabia. Choosing the right metal cutter is very important for optimal productivity, cost-effectiveness, and long-term sustainability. This article elaborates on the 10 most important considerations while purchasing metal-cutting equipment in Saudi Arabia.

1. Type of Metal to Be Cut

The type of metal that will finally be cut becomes one of the very first criteria for purchasing metal-cutting equipment. Cutting different metals requires different techniques and tools. For instance, high cutting forces are required when cutting steel, whereas less power but more speed is needed with softer metals, such as aluminium. The kind of cutting equipment needs to jibe with the characteristics of the metal to achieve efficient cutting but also to minimize unnecessary tool wear. If the equipment is to be used with a particular metal, it increases its performance and life.

2. Speed and Efficiency of Cutting

Cutting speed is one among those many points that determine the buy decision of metal cutting equipment. The faster metal can be cut without compromising good finish quality, the more productive one is. Speedy cutting leads to heavy outputs, supplemented with reduced costs, which mainly hold in large-scale manufacturing. Precision needs to be maintained by such speed, for excessive speed might damage the material itself. Variable cutting speeds could be preferred for projects/materials with high flexibility.

3. Precision and Accuracy

Precision is the chief concern in a metal cut, especially for industries that require parts with very close tolerances like aerospace, automotive, or electronics. Equipment featuring such precision gives an accurate cutting dimension, which eliminates the requirement for further processing and results in minimal wastage of material. The tools need to have positioning devices combined with CNC provisions so that they can accurately cut down to micrometres. Such precision proves to be significant in satisfying the great requirement of trade in some industries.

4. Durability and Build Quality

Another factor is durability, and it is most applicable in the case of heavy-duty-cutting equipment. The use of high-quality materials and robust construction guarantees that equipment withstands the rigours of industrial applications. Durability also means less downtime for repairs and replacements, which, in turn, means improved efficiency and savings. Go for equipment that is made from high-grade metals or alloys that have been designed to endure wear and tear. Invest in durable equipment to cut down on the long-term cost of ownership.

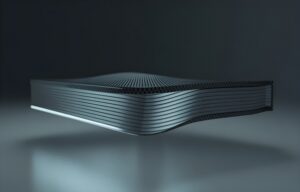

5. Technological and Automation Features

Modern machines for metal cutting usually come along with automated features such as CNC technology, laser cutting, and plasma cutting, making their application extremely productive and also precise. Among the various ways wherein these technologies help in the concluded production of parts, preeminently among them are consistency, reduced chances for human errors, and achieving higher-quality finishes. Consider machines that integrate technologies to streamline a good number of operations, therefore minimizing labor costs, and improving speed and accuracy. With automation, faster production rates can also be achieved without compromising quality.

6. Cost and Budget Considerations

Cost is, of course, one of the affecting factors but not the sole criterion for selecting machinery. It might be very inexpensive to buy, but later it may have to be disposed of and cause a lot of cost in maintenance or perhaps inefficiency in the long run. Evaluate the total cost of ownership, i.e., purchasing price, maintenance and longevity of the machine. Consider equipment that gives the maximum value for money without compromising quality. Higher quality would generally result in long-term savings.

7. Maintenance and Support Services

Good metal-cutting equipment, however, would need reliable maintenance services and after-sales support. Find out whether the supplier provides training, troubleshooting and qualified technicians. Inquire also if spare parts are available in Saudi Arabia to prevent a long delay before repairs. Support services may be vital in reducing production interruptions and enhancing dependable operation. Regular maintenance checks also extend the lifespan of the equipment, reducing long-term costs.

8. Size and Space Requirements

Consider space within your plant before deciding to acquire it. Larger machines take up a lot of floor space, whereas compact models fit well in tighter environments. Make sure it integrates with your existing setup, not a space issue. If you are short of space, consider looking for modular or smaller equipment that still meets your performance needs. Efficient use of space improves workflow efficiency and prevents overcrowding, leading to better overall organization. Proper space planning also ensures that your equipment is easily accessible for maintenance and operation.

9. Safety Features

Greatly, the safety of the purchase relates to the industrial equipment. Machines must-have features that include automatic shut-off devices, emergency stop buttons, safety enclosures, etc. Additionally, make user-friendly interfaces in equipment so that operators do not make errors. Inspection and training only would maintain a conducive environment in the workplace. Therefore, features can save many accidents from happening and even help boost productivity. Moreover, keeping safety measures up to date ensures compliance with industry standards and reduces the risk of liability.

10. Environmental Impact and Energy Efficiency

Energy-efficient cutting equipment minimizes the cost of operations while laying a small carbon footprint. State-of-the-art energy-efficient appliances aim at waste reduction and emissions for ecological preservation. Select such equipment for improvement of the pride of your company and compliance with environmental regulations since sustainability is a key role in Saudi Arabia. Sustainable practices within equipment use also keep pace with global trends toward reduction in environmental impact.

Choosing a cutting tools equipment company in Saudi Arabia requires you to evaluate several factors considering the process of cutting the metal type up to future costs and environmental impacts. As you consider and prioritize your needs and core issues importantly on precision, durability, cost-effectiveness, and safety, your investment in metal cutting tools will do a great job to answer for growth and efficiency in the business. The correct equipment can keep your business very competitive in Saudi Arabia’s expanding industrial market, as well as smoothness and efficiency during production processes.