Selecting the Best Plastic Materials for Your Injection Molding Production

1 min read

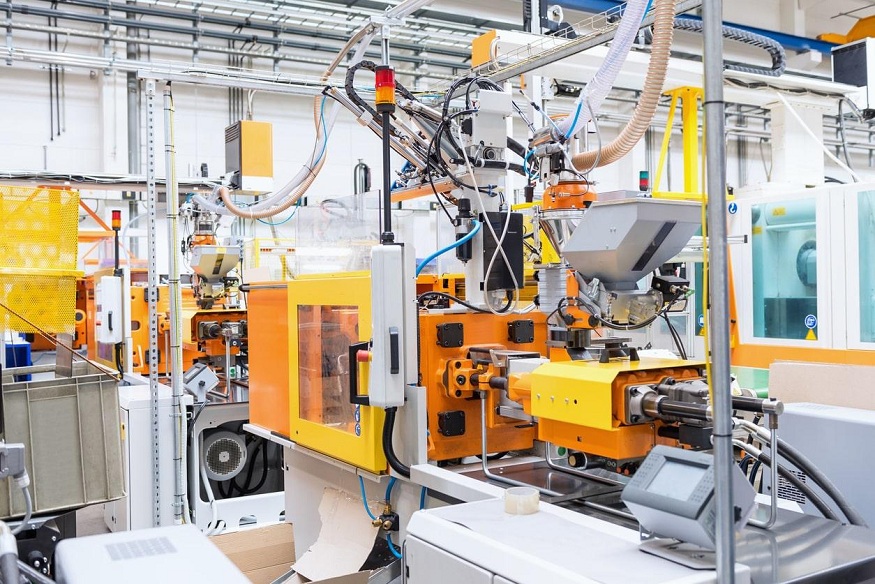

Choosing the appropriate material for injection molding is critical to the performance and quality of your product. Each type of plastic has its own set of strengths and weaknesses, which are crucial to understand in order to select the most suitable material for your specific needs. Whether it’s for manufacturing food packaging, medical instruments, vehicle parts, or heavy-duty industrial machinery, the choice of material significantly influences how well the part will stand up to temperature variations, chemical exposure, and other environmental challenges.

In the realm of plastic injection molding, the material selected profoundly affects essential attributes of the manufactured item, such as its durability, flexibility, and degree of clarity. For example, ABS plastic is celebrated for its considerable strength and stiffness, whereas polypropylene is valued for its elasticity and thermal resistance. Each option introduces unique traits that are vital to evaluate in light of your project’s specific requirements.

This resource delves into the advantages and drawbacks of various popular plastics utilized in injection molding, from the superior thermal resistance of Nylon to the outstanding recyclability and transparency of PET. By gaining a thorough understanding of each material’s properties, you can make a well-informed choice that enhances both the efficiency and cost-effectiveness of your production workflow.