From Concept to Cabin: The Material Choices Behind Modern Aircraft

3 min read

aircraft composite technologies

Step inside any modern airplane and you’re surrounded by thousands of materials. Each one got picked for a reason. Better materials drove the change from biplanes to jets. Engineers agonize over every decision. Make a mistake and airlines won’t buy your plane.

Starting with the Structure

Aluminum owned aviation for a long time. Strong enough, light enough, cheap enough. Problem is, salt air eats at it. Fly the same route enough times and tiny cracks spider across the metal. Lightning hits aluminum and travels right through it. So planes today mix things up. The body might have aluminum here, carbon fiber there. Wings bend just right during flight thanks to composites that weigh half what aluminum does. Rust and corrosion? These materials don’t even know what that means. Lightning hits the plane but merely glances off it. The people at Aerodine Composites explain that aircraft composite technologies let planes reach altitudes and speeds that would’ve seemed like magic to early aviators.

Titanium is often used in high-stress areas like landing gear. Sure, your wallet feels it. But titanium shrugs off punishment that would snap other metals in half. Freeze it, roast it, hammer it – titanium does not care. Spend money on titanium now or spend way more fixing catastrophic failures later.

Inside the Engines

Jet engines beat the hell out of materials. We’re talking temperatures that turn steel into pudding. Forces that would rip a car in half, happening over and over, thousands of times each second. Regular metals would last about five seconds in there. That’s why turbine blades get made from nickel alloys that most folks can’t even pronounce. These things stay solid at 2,000 degrees. Then engineers spray ceramic coatings on top because apparently that’s still not enough protection. Some engine parts? They grow them as one giant crystal. Without seams, cracks can’t form.

The engine’s outer shell tells a different story. Composites wrap around that screaming hot core, keeping noise down without adding much weight. If something breaks loose inside, these materials catch the shrapnel before it punches through and ruins everyone’s day.

Creating Comfortable Cabins

Passenger seats look simple but hide complex engineering. They have got to pamper your backside for hours while also surviving crash tests. So manufacturers mix fancy plastics with lightweight metals. The foam fights fires. The fabric shrugs off coffee spills and won’t burst into flames. Those overhead bins? They’re not just plastic boxes. They’re composite puzzles that hold your overstuffed luggage without buckling. Slam them shut a thousand times and they still work smooth as butter. Hit turbulence and they flex instead of dumping bags on your head.

Windows really make engineers earn their paychecks. The pressure difference between inside and outside wants to blow them out. Scratches and cracks could spell disaster. So planes use layered plastics, not glass. Lightweight, clearer over time, and safer than glass.

The Hidden Systems

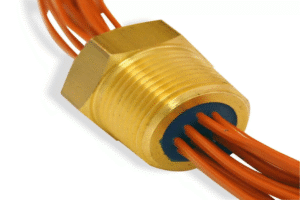

Open up the walls and you will find miles of cables. Copper got kicked out for being too heavy. Aluminum took over for a while. Now fiber optic cables shoot information around using light. A bundle of old wires as thick as your arm gets replaced by fibers thinner than hair. Nobody thinks about insulation until it fails. Cruising altitude outside an airplane is minus 70. Aerogel insulation prevents freezing with superior cold-blocking ability. Engine roar becomes a hum with sound padding.

Conclusion

Each new plane uses past experience. Materials scientists are advancing, producing things that were once science fiction. This work makes flying safer, cheaper, and more pleasant.