Integrating Smart Technology with Industrial Brushes for Enhanced Monitoring and Control

4 min read

Imagesuggestions:

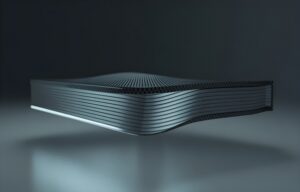

ImageofaSmartIndustrialBrushwithEmbeddedSensors:

- A close-up photograph of an industrial brush equipped with visible embedded sensorsand connectivity features.

- The image can showcase the integration of smart technology in the brush, highlighting components like pressure sensors, wear indicators, and connectivity modules.

- Thiswillvisuallyrepresenttheconceptofsmarttechnologyintegrationinindustrial brushes, making the technical aspects more relatable and understandable for readers.

ImageofaSmartIndustrialBrushinAction:

- A dynamic shotofasmartindustrialbrushinusewithinamanufacturingsetting,withan overlay of data analytics graphics (e.g., real-time performance metrics displayed on a screen).

- This image should capture thebrushoperatingonametalorautomotivepart,illustrating real-time monitoring and control.

- This will demonstrate the practical application and benefits of smart industrial brushes, showing how real-time dataandmonitoringenhancetheefficiencyandqualityofsurface finishing processes.

Call toAction:Unlockthefutureofsurfacefinishingwithsmarttechnologyintegratedindustrial brushes from Aviva Brushes. Enhance your monitoring and control processes today. Visit our website to learn more!

Social Post Summary:Discover how integrating smart technology with industrial brushes is revolutionizing surface finishing in various industries. Our latest blog explores the benefits of enhanced monitoring and control through advanced sensors, real-time data, and automated processes. Learn how leading brush manufacturers in India, like Aviva Brushes, are at the forefront of this innovation. From automotive and aerospace to metalworking and municipal cleaning, smart industrial brushes are improving efficiency, reducing downtime, and ensuring superior quality. Embrace the future of surface finishing with insights into key components, implementation strategies, and future trends in smart technology. Read the full blog on our website and see how you can optimize your manufacturing processes with the latest advancements in industrial brushes. #IndustrialBrushes #SmartTechnology #SurfaceFinishing #AvivaBrushes #InnovationInManufacturing.

TableofContents:

Introduction

UnderstandingSmartTechnologyinIndustrialBrushes What is Smart Technology?

Key Components of Smart Industrial Brushes Benefits of Integrating Smart TechnologyApplications of Smart Industrial Brushes ImplementingSmartTechnologyinIndustrialBrushes Challenges and Solutions

FutureTrendsinSmartIndustrialBrushes Conclusion

Industrial brushes have long been indispensable tools in various industries, ensuring smooth finishes, efficient cleaning,and precise polishing. With the rapid advancement of technology, integrating smart technology into these brushes has become a game-changer. Brushmanufacturers in India, such as Aviva Brushes, are at the forefront ofthisinnovation,offering enhanced monitoring and control solutions that revolutionize the use of industrialbrushes.This blog explores the integration of smart technology with industrial brushes, highlighting itsbenefits, applications and future trends.

UnderstandingSmartTechnologyinIndustrialBrushes What is Smart Technology?

Smart technology refers to the use of advanced sensors, data analytics and automation to enhance the functionality of traditional tools. In the context of industrial brushes, it involves embedding sensors and connectivity features to monitor performance and provide real-time data.

KeyComponentsofSmartIndustrialBrushes:

- Sensors:Measureparameterssuchasbrushwear,pressureand

- Connectivity:Enablesdatatransmissiontomonitoringsystemsfor

- DataAnalytics:Processescollecteddatatoprovideactionable

BenefitsofIntegratingSmartTechnology:

- Enhanced Monitoring:Smart brushes offer real-time monitoring of brush condition, usage, and performance. This enables proactive maintenance, reducing downtime and extending brush life.

- Improved Control:Automation and precise control of brush operations ensure consistent and high-quality surface finishes. Adjustments can be made on-the-flybased on real-time data.

- Increased Efficiency:By optimizing brush performance and maintenance schedules, smart technology reduces operational costs and increases overallefficiencyinindustrial

ApplicationsofSmartIndustrialBrushes:

- Automotive Industry:In the automotive industry, smart brushes are used for precise polishing and cleaning of components. Real-time monitoring ensures that brushes are functioning optimally, leading to better surface finishes and reduced defects.

- Aerospace Industry:Aerospace manufacturersutilizesmartbrushesfordeburringand finishing aircraft parts. The enhanced control and monitoring capabilities ensure compliance with strict quality standards and improve the overall performance of

- Food Processing Industry, where hygiene and precision are paramount. Smart industrial brushes equipped with advanced sensors and connectivity features ensure thorough cleaning of processing equipment and conveyor belts. Real-timemonitoringof brush condition and performance helps maintain strict hygiene standards, preventing contamination and ensuring product safety.

- Textile Industry: This industry benefits greatly from smart industrial brushes in various stages of production, including fabric finishing and cleaning. The brushes, integratedwith sensors, monitor brush performance and wear, ensuring consistent quality infabric treatment processes. Real-time data allows for precise adjustments, enhancing the efficiency of brushing operations such as removing lint, polishing fabric surfaces, and cleaning machinery.

- Municipal Cleaning:Aviva Brushes are integrated with smarttechnologyformunicipal cleaning tasks. These brushes ensure efficient street sweeping and debrisremovalwith minimal manual intervention, enhancing urban cleanliness and safety.

ImplementingSmartTechnologyinIndustrialBrushes:

- Choosing the Right Sensors: Selecting appropriate sensors for monitoring brush parameters is crucial. Common sensors include wear sensors, pressure sensors, and temperature sensors.

- Integrating Connectivity Features:Implementing connectivity features such as IoT (Internet of Things) allows for seamless data transmission and remote monitoring. This enables real-time adjustments and proactive maintenance.

- Utilizing Data Analytics:Advanced data analytics tools process the collected data, providing insights that help in optimizing brush performance and maintenanceschedules. This ensures that brushes are used efficiently and effectively.

ChallengesandSolutions:

- HighInitialCosts:However,the long-term benefits, such as reduced maintenance costs and increased efficiency, often outweigh the initial expenditure.

- Data Security:Ensuring the security of transmitted data is essential. Implementing robust encryption and secure communication protocols can mitigate security risks.

- Technical Expertise:Integrating smart technology requires technical expertise. Collaborating with technology providers and investing in training for personnel can address this challenge.

FutureTrendsinSmartIndustrialBrushes:

- Advanced Materials:The development of new materials for sensors and brushes will enhance durability and performance. Innovations in materials science will lead to more efficient and longer-lasting brushes.

- AI and Machine Learning:Artificial intelligence and machine learning will play a significant role in analyzing data and predicting maintenance needs. This will further optimize brush performance and reduce downtime.

- Increased Customization: The demand for customized smart brushes tailored to specific industrial needs will rise. Manufacturers willoffermorepersonalizedsolutionsto meet unique requirements.

- Sustainability:Sustainable practices, including the use of eco-friendly materials and energy-efficient technologies, will become more prevalent in the production of smart industrial brushes.

Conclusion:

Integrating smart technology with industrial brushes is transforming the way industries monitor and control their surface finishing processes. With real-time data, enhanced control and increased efficiency, smart brushes offer numerous benefits across various applications. Brush manufacturers in India, like Aviva Brushes, are leading this technological revolution, providing innovative solutions that enhance the functionality and effectiveness of industrial brushes. As technology continues to advance, the future holds even greater potential for smart industrial brushes, promising improved performance, sustainability and customization.